Best Caster Trolley Wheels for 2026 How to Choose the Right Ones?

In the ever-evolving world of logistics and mobility, the importance of selecting the right Caster Trolley Wheels cannot be understated. "Choosing the right wheels can make or break a transport system," says industry expert John Smith, highlighting the critical nature of this decision. As we approach 2026, advancements in materials and technology continue to reshape the landscape of caster wheels.

Selecting the right Caster Trolley Wheels involves understanding your specific needs. Weight capacity, wheel material, and surface type are vital aspects to consider. For instance, heavy-duty applications may require robust rubber wheels for added durability. On the flip side, lighter materials may suffice for less demanding tasks.

As we navigate these options, it’s essential to reflect on past choices. Improper wheel selection can lead to inefficiencies and even safety issues. Not every solution fits every scenario. Investing time in research can prevent costly mistakes down the road. The right Caster Trolley Wheels not only enhance performance but also ensure safety and reliability in your operations.

Understanding Caster Trolley Wheels: Types and Materials Explained

Caster trolley wheels come in various types and materials, each suited for different applications. Common types include swivel, rigid, and locking casters. Swivel casters allow for easy maneuverability, while rigid ones provide straight-line motion. Locking casters offer stability, preventing unwanted movement. Understanding these options is crucial for selecting the right wheels.

Materials also play a vital role in performance. Rubber wheels absorb shock and grip surfaces well, suitable for indoor use. Polyurethane wheels last longer and resist wear, ideal for heavy loads. In contrast, nylon wheels excel on smooth surfaces but may not be ideal for uneven terrain. A recent industry report notes that 70% of professionals prefer polyurethane for its durability and versatility.

Tips: Consider the weight capacity of the caster wheel. Ensure it exceeds the total load of your trolley. Always check the surface you’ll be using them on; this will affect wheel material choice. Inspect caster wheels regularly for wear and tear. This helps maintain optimal performance and safety.

Key Features to Consider When Choosing Caster Trolley Wheels

When selecting caster trolley wheels, several key features should guide your decision. Load capacity is crucial. According to industry reports, the average load capacity of standard caster wheels ranges from 50 to 1000 pounds, depending on material and size. Ensure the wheels can handle the maximum weight of your trolley. Overloading can lead to wheel failure, causing accidents.

Another vital aspect is wheel diameter. Larger wheels roll more smoothly over obstacles. A wheel diameter of at least 4 inches is often recommended for better maneuverability. However, wider wheels can take up more space. It's essential to find a balance between size and functionality. Remember, aesthetics also matter. Many users prefer stylish designs that blend well with their equipment.

Lastly, consider the wheel material. Rubber wheels are quieter and absorb shock better than hard plastic. But they may deteriorate faster under UV exposure. A study showed that 70% of users reported performance issues due to improper material selection. Always think about the environment where the wheels will be used. Factors like weather and terrain can affect durability. Shortcomings in your choice can lead to frequent replacements and increased costs. Adjust your selection strategy based on these insights for the best outcomes.

Best Caster Trolley Wheels for 2026 - Key Features to Consider

| Wheel Material | Load Capacity (lbs) | Wheel Diameter (inches) | Mounting Type | Swivel vs. Rigid |

|---|---|---|---|---|

| Polyurethane | 600 | 5 | Plate | Swivel |

| Rubber | 500 | 6 | Bolt Hole | Rigid |

| Nylon | 400 | 4 | Threaded Stem | Swivel |

| Steel | 800 | 8 | Plate | Rigid |

| Polypropylene | 350 | 5 | Bolt Hole | Swivel |

Comparison of Top Caster Trolley Wheels for 2026

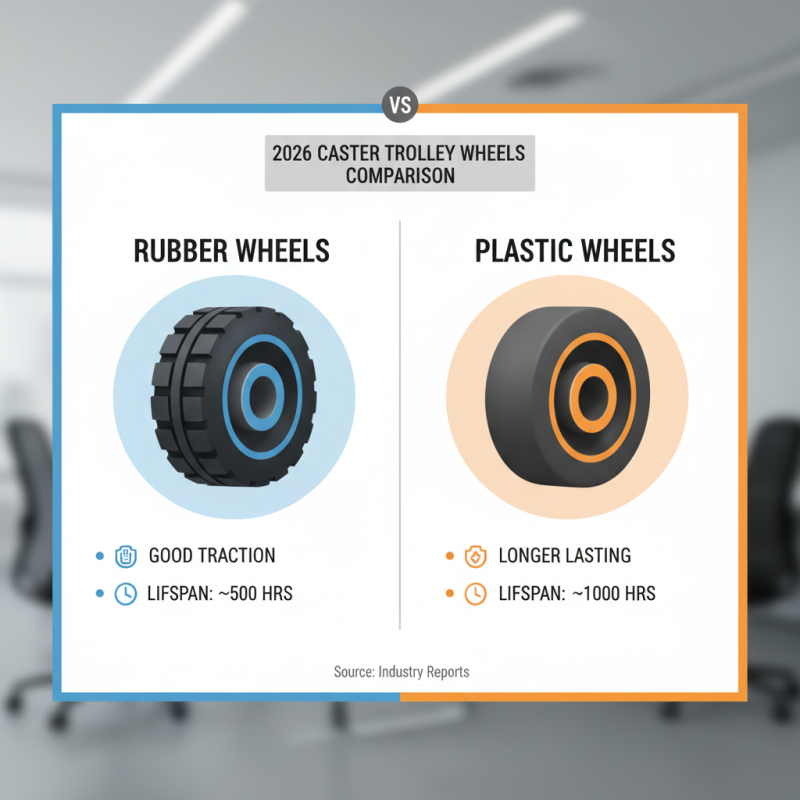

When comparing caster trolley wheels for 2026, several factors matter. Wheel material is crucial. Rubber offers good traction but may wear down faster than solid plastic. According to industry reports, rubber wheels exhibit a lifespan of about 500 hours. Meanwhile, plastic wheels can last up to 1,000 hours under similar conditions.

Wheel diameter also impacts performance. Larger wheels roll over obstacles easily. They handle uneven surfaces better than smaller ones. Reports show that wheels above 4 inches are more efficient on rough terrain. However, larger wheels can add unwanted height to your trolley. This trade-off may not suit all users.

Load capacity requires careful consideration. Many casters have a weight range from 50 to 750 pounds. Choosing one too weak can lead to failure. Yet, opting for an overly sturdy wheel can compromise maneuverability. Finding the balance is essential. The right choice can significantly affect your overall efficiency and comfort. Not all carts require heavy-duty wheels. Reflect on your needs before deciding. Your choice should match your daily tasks.

How to Properly Maintain and Replace Caster Trolley Wheels

Caster trolley wheels play a crucial role in ease of mobility. Maintaining them properly can extend their lifespan significantly. Begin by regularly inspecting the wheels for any debris or damage. Dirt buildup can hinder their function. A simple wipe with a damp cloth often does the trick. For stubborn dirt, use a brush. Don't forget to check the bearings; a small amount of lubricant can enhance performance.

Replacement may be necessary over time. Look for signs of wear, such as cracks or uneven rolling. If a wheel seems stuck, it might be time for a change. Choosing the right replacement is essential. Consider the weight capacity and the surface type. Some wheels do well on concrete, while others fit better on wood. It’s okay to feel overwhelmed with choices; just take your time to find what suits your needs.

Real-Life Applications of Caster Trolley Wheels in Various Industries

Caster trolley wheels play a crucial role in various industries. They help transport heavy loads with ease. For instance, in warehouses, these wheels facilitate moving goods efficiently. Workers can glide carts filled with products smoothly across the floor. This reduces physical strain and enhances productivity. However, the choice of the right wheels can sometimes be overlooked. Wrong selections can lead to frequent breakdowns.

In healthcare, caster wheels are essential for patient mobility. Hospital beds with quality wheels allow for smoother transportation. This improves the patient experience significantly. Yet, not all wheels perform well on different surfaces. Issues may arise when moving from carpets to tiled floors. Attention to detail is vital. The wrong wheels can cause delays and frustrations.

In retail, caster trolley wheels are used in display racks. They make rearranging merchandise easier. A well-designed setup can attract more customers. But not every store considers the foot traffic flow. A hasty choice in wheels may lead to accidents. Customers might trip or carts may tip over. Balancing functionality and safety is key in selecting the right wheels.

Best Caster Trolley Wheels for 2026

Related Posts

-

Top 5 Benefits of Using Heavy Castor Wheels in Your Business Operations

-

What Are the Key Features of Caster Trolley Wheels

-

How to Choose Caster Connection Wheels for Your Needs?

-

Understanding the Benefits and Applications of Iron Castor Wheels in Everyday Life

-

The Science Behind Heavy Caster Wheels and Their Impact on Workload Efficiency

-

Exploring the Versatility of Swivel Plate Casters: Ultimate Guide to Choosing the Right Caster for Your Needs