Best Stainless Casters for Smooth Mobility Which One to Choose?

When it comes to moving equipment smoothly, "Stainless Casters" play a crucial role. According to recent industry reports, businesses experience a 30% increase in efficiency by using high-quality casters. Stainless casters are particularly valued for their durability and resistance to corrosion. This makes them perfect for environments such as kitchens, hospitals, and warehouses.

However, choosing the right stainless casters isn’t straightforward. Factors such as load capacity, wheel size, and surface material can complicate the decision-making process. Many buyers overlook these aspects. A mismatched caster can lead to increased wear and tear on both the caster and the surface it moves on.

The variety of available options can also be overwhelming. Various styles and features cater to different needs. As a result, some may find themselves settling for inadequate choices. A deeper understanding of stainless casters could prevent these pitfalls. Making a well-informed choice is essential for achieving optimal performance and longevity in your mobility solutions.

Understanding the Importance of Stainless Casters for Mobility

Stainless casters are essential for smooth mobility in various settings. These components are designed to enhance movement. They provide reliability and durability, ensuring a seamless experience. In workplaces or kitchens, mobility can significantly improve efficiency. Heavy equipment or storage units become easier to relocate.

Selecting the right caster can be daunting. It’s important to consider load capacity, wheel size, and surface type. Some casters excel on smooth surfaces. Others struggle on rough terrain. This variability means testing is crucial. A caster that works well in one scenario may falter in another.

Maintenance is also key. Rust can develop over time, especially in humid areas. Regular cleaning helps preserve functionality. Inspecting for wear ensures casters work as intended. Mobility issues can arise if they are neglected. Overall, understanding these aspects is vital for optimal performance. A little thought can go a long way.

Types of Stainless Casters and Their Suitable Applications

When choosing stainless casters, it's essential to consider the types available and their specific applications. There are several varieties, including swivel, fixed, and locking casters. Swivel casters allow for easy maneuvering, making them ideal for tight spaces. Fixed casters, however, are better for straight-line movement and are often used on heavy equipment. Locking casters provide added stability, helping to keep items in place when needed.

When selecting casters, think about the environment. For example, stainless steel casters are excellent for environments where moisture is an issue. They resist rust and corrosion. In contrast, polyolefin casters might be a better choice for indoor use, offering a smoother glide over surfaces. Assess the weight capacity as well. Using a caster that isn’t rated for the load can lead to problems over time.

It’s crucial to account for the specific needs of your application. Not every type works for every situation, and it can be easy to overlook this. If not used correctly, casters can wear out quickly. Always consider the flooring type, as hard surfaces differ from carpeted ones. Reflect on the overall design of your setup, ensuring the chosen casters align perfectly with your goals.

Factors to Consider When Choosing Stainless Casters

When selecting stainless casters, several factors come into play. The size and weight capacity of the caster is crucial. A larger caster may have better weight distribution and can handle heavier loads. However, it might not always fit into tight spaces. Conversely, smaller casters are ideal for narrow areas but may lack durability.

Material quality is another consideration. High-quality stainless steel is more resistant to corrosion and rust. This is particularly important in environments like kitchens or hospitals. You might think all stainless steel is the same, but there are variations in grade and finish.

Tip: Always check load ratings. It’s vital to choose a caster with a load rating that exceeds your maximum requirement. This will ensure longevity and prevent accidents.

Another aspect to evaluate is the type of wheel. Hard wheels roll easily on smooth floors. Soft wheels are better for uneven surfaces. Remember that having the right wheel can significantly affect mobility.

Tip: Consider using swivel casters for greater range. They can move in any direction, offering flexibility in crowded spaces. But be cautious; they can also make control harder if overloaded. Choose wisely, as the right stainless caster can improve mobility and efficiency significantly.

Comparative Analysis of Top Stainless Caster Brands

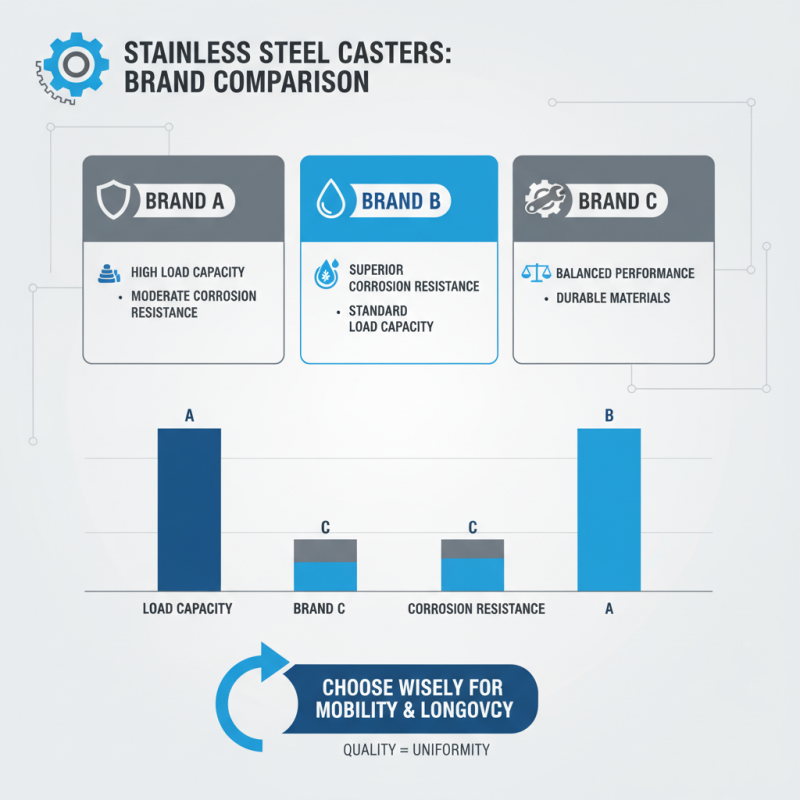

When selecting stainless casters, understanding the differences among various brands is crucial. High-quality materials ensure durability, but not all brands offer the same performance. Some may excel in load capacity, while others might focus on corrosion resistance. Each factor plays an essential role in mobility.

Tips: Always check the weight rating. Overloading can cause wheels to fail. Consider the surface type too. Soft wheels work well on uneven floors, while hard ones are better on smooth surfaces.

A common misconception is that expensive means better. While premium options often come with advanced features, not everyone needs these extras. Sometimes, a simple caster can perform just as well with proper care. Reflect on your specific needs before investing.

Tips: Regular maintenance extends caster life. Clean wheels to avoid debris build-up. Don’t forget to inspect for wear and tear regularly. Small issues can lead to bigger problems down the road.

Maintenance Tips for Long-lasting Performance of Stainless Casters

When it comes to stainless casters, maintenance is key to ensure smooth mobility. One common issue faced in various industries is corrosion. According to a report by the American Society for Testing and Materials, about 50% of machinery failures arise from inadequate maintenance. Regularly inspecting stainless casters for signs of wear can prevent costly downtimes.

Cleaning is essential. Dirt and debris can cause casters to malfunction. It's recommended to use a gentle detergent and warm water. Avoid abrasive materials that could scratch the surface. Annual lubrication of swivel components helps to maintain smooth rotation. A study by the National Association of Manufacturers indicates proper lubrication can extend the life of casters by up to 30%.

Another critical aspect is weight load management. Casters have specific weight limits. Overloading them can lead to premature failure. A frequent mistake is assuming that all casters can handle the same load. This requires vigilance and record-keeping of the weight distribution in work environments. Regular checks and adjustments can greatly enhance longevity and prevent hazards.

Related Posts

-

10 Essential Tips for Choosing the Best Stainless Casters for Your Business

-

Ultimate Guide to Choosing the Right Stainless Casters for Your Needs

-

The Future of Cast Iron Casters in Sustainable Manufacturing

-

Innovative Solutions for Cast Iron Caster Applications

-

Understanding Common Issues with Caster Swivel Solutions

-

How to Choose the Right Iron Castor Wheels for Your Project