How to Choose Caster Connection Wheels for Your Needs?

When it comes to selecting the right Caster Connection Wheels, the choices can be overwhelming. These wheels play a vital role in ensuring mobility and ease of use for various applications. It’s essential to consider factors such as weight capacity, wheel material, and size. Each detail matters when creating a functional environment.

Choosing the right wheels isn’t a one-size-fits-all affair. You must think about how you will use them. Are you moving heavy equipment or lightweight items? The performance and durability vary significantly. Sometimes, you might overlook the specific needs of your setup, resulting in less than ideal wheel selection.

In the end, understanding your exact requirements is crucial. Ask questions and seek advice if necessary. The process might not be straightforward, and you might make mistakes along the way. But with careful consideration, you can select Caster Connection Wheels that truly meet your needs.

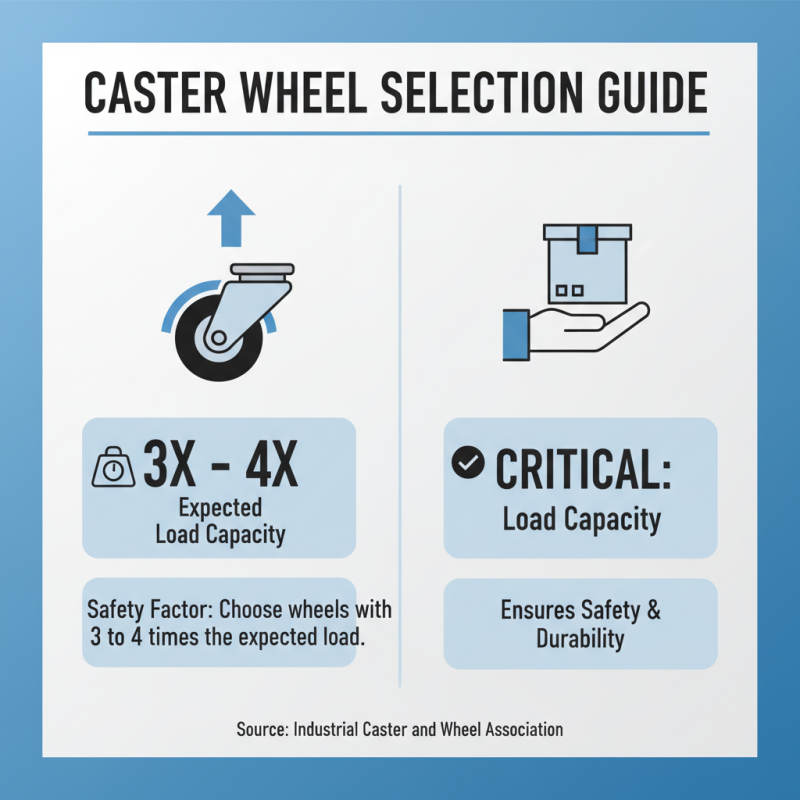

Consider the Load Capacity Requirements for Caster Connection Wheels

When selecting caster connection wheels, load capacity is critical. The right wheels should handle the weight of your application without sacrificing performance. According to the Industrial Caster and Wheel Association, choosing wheels with a capacity that is three to four times the expected load is advisable. This precaution ensures safety and durability.

Calculating load capacity can be complex. Start by determining the total weight of the equipment or furniture. Include any additional weight from items being transported. It’s essential to consider dynamic loads, too. These can change as the wheels move, causing stress. Different materials have varying load capacities. For instance, rubber wheels typically support less weight than steel ones.

Misjudging load requirements can lead to issues. Undercapacity can cause wheel failure, resulting in downtime. On the other hand, overcapacity can lead to unnecessary costs. Choosing the right size and type impacts efficiency. It's often tempting to opt for cheaper alternatives. However, this may compromise safety and longevity. Well-researched decisions lead to better outcomes.

Evaluate Different Wheel Materials Based on Application Needs

When choosing caster connection wheels, it's essential to consider the materials based on your application needs. Different materials offer varied benefits and drawbacks. For indoor use, softer rubber wheels provide silent operation and protect floors. However, they may wear down quickly on rough surfaces. For outdoor applications, harder materials like polyurethane can withstand harsh conditions and provide durability.

Here are some tips to help you select the right wheels. First, assess the surface type where the wheels will be used. Smooth surfaces favor softer materials, while rough terrain requires tougher options. Keep in mind that weight capacity matters. Some materials excel at bearing heavy loads, while others could deform or fail. Take note of the environment too. Will the wheels be exposed to chemicals or extreme temperatures? Choose materials resistant to such conditions.

Another key factor is noise level. If noise is a concern, look for wheels designed for quiet rolling. They might be slower but can enhance comfort. Always remember, there's no one-size-fits-all solution. Testing different wheels can be insightful. What works well for one application may not meet another's needs. Don't hesitate to experiment and adjust your choices.

Understand Wheel Size and Diameter Impact on Performance

When selecting caster connection wheels, understanding wheel size and diameter is crucial. The diameter directly affects how a wheel performs under different loads and surfaces. Larger wheels roll over obstacles more easily. They are ideal for uneven surfaces. Smaller wheels may struggle in these conditions. But they can pivot and maneuver better in tight spaces. This creates a trade-off that must be considered.

Consider your specific needs when choosing the diameter. If your environment includes ramps or bumps, larger wheels are often best. However, if you require sharp turns, a smaller size might be more efficient. The challenge lies in finding the perfect balance. Often, users overlook these subtleties. They might focus solely on load capacity and miss how diameter influences mobility. Ultimately, it's helpful to reflect on the environment where the wheels will be used. Will you be moving heavy items over rough floors? Or navigating tight corners? Each scenario demands a different wheel size.

Impact of Wheel Size and Diameter on Performance

Assess Swivel vs. Rigid Casters for Mobility and Control

When choosing caster connection wheels, understanding the difference between swivel and rigid casters is essential. Swivel casters allow for easier maneuverability. They can rotate 360 degrees, making them ideal in tight spaces. According to industry data, about 70% of users prefer swivel casters for dynamic environments. This preference showcases their versatility in diverse applications, from warehouses to hospitals.

Rigid casters, on the other hand, provide stability and directional control. They move straight and are perfect for heavier loads. Research indicates that many operations report a 20% increase in efficiency when utilizing rigid casters in fixed pathways. However, they can be less flexible in navigating corners and can require more effort to reposition.

Ultimately, the choice between swivel and rigid casters depends on specific needs. If agility is a priority, swivel casters are the way to go. Yet, for heavy-duty needs, rigid casters shine. Balancing these options can be tricky. Users must reflect on their unique scenarios to make the best decision. Consider load requirements and workspace dynamics before settling on a type.

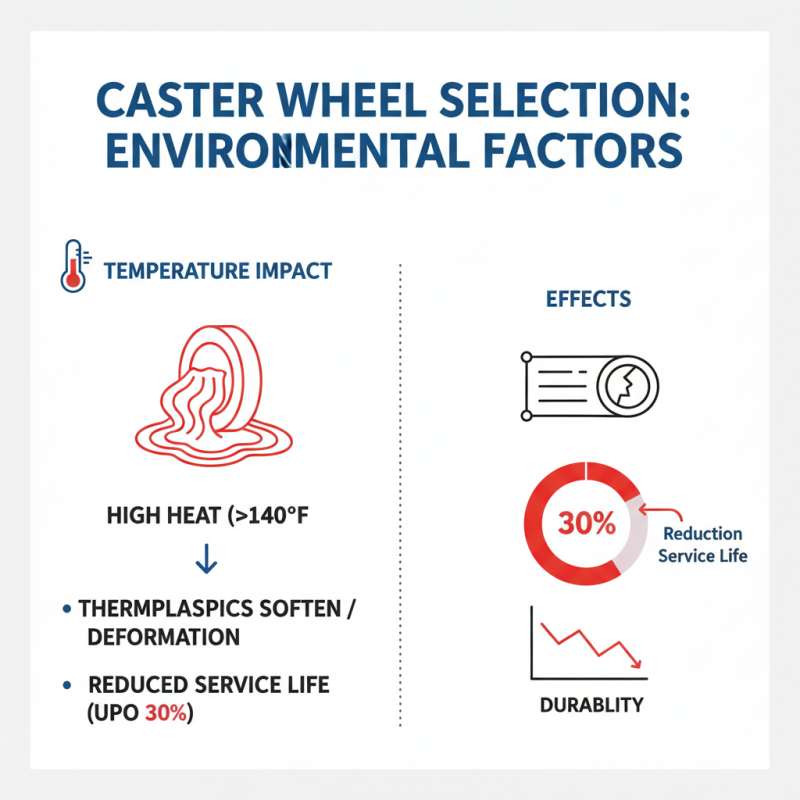

Check for Environmental Factors Affecting Caster Performance

When selecting caster wheels, environmental factors play a crucial role. Temperature variations can significantly impact wheel materials. For instance, thermoplastics may soften in high heat, leading to deformation. A study showed that wheels exposed to temperatures above 140°F experienced a reduction in service life by up to 30%.

Humidity is another critical factor. High moisture levels can cause rust and corrosion in metal casters. According to industry reports, casters exposed to humid environments can lose structural integrity over time. Wheels used in food service should resist moisture, while manufacturing environments may require abrasion-resistant materials.

Beyond these elements, surface conditions should be considered. Rough or uneven surfaces can cause increased wear on wheels, leading to premature failure. A recent survey indicated that 25% of caster problems arose from improper surface selection. Choosing the right wheel for your specific environment is vital for ensuring optimal performance and longevity.

Related Posts

-

How to Choose the Right Caster Trolley Wheels for Your Needs

-

Understanding the Challenges of Heavy Caster Wheels in Industrial Applications

-

Top 5 Benefits of Using Heavy Castor Wheels in Your Business Operations

-

What is Iron Castor Wheels and Why You Should Choose Them for Your Projects

-

What Are the Key Features of Caster Trolley Wheels

-

What are the Advantages of Caster Trolley Wheels for Your Business