Essential Tips for Choosing the Right Swivel Plate Caster?

Choosing the right Swivel Plate Caster can significantly impact your mobility and efficiency. It determines how easily your equipment moves. With various options available, making the right choice often feels overwhelming.

Consider the weight capacity first. Each caster has different load limits. Selecting one that meets your needs is crucial. Pay attention to the wheel material too. Rubber wheels offer smooth motion, while metal wheels provide durability on rough surfaces. Think about where you'll use them.

Don't overlook the mounting plate's size. A mismatch can lead to instability. Additionally, the swivel feature is essential for maneuverability. Excessive swivel can complicate straight-line movement. Reflect on your specific requirements, and don’t hesitate to experiment. A perfect choice might not exist, but finding the best fit is achievable with careful thought.

Understanding Swivel Plate Casters and Their Applications

Swivel plate casters are versatile tools widely used in various industries. They facilitate movement for carts, equipment, and furniture. According to a recent market report, the global caster market is expected to grow at a CAGR of 4% over the next five years. This growth highlights the increasing demand for efficient movable solutions in warehouses and factories.

When selecting swivel plate casters, consider the weight capacity. Each type supports different loads. A heavy-duty caster can bear over 1,200 pounds. Make sure you know the weight of your application before making a choice. Also, wheel material matters. Hard wheels work well on smooth surfaces, while soft wheels are better for uneven terrains.

Tip: Observe your environment. What surface will the casters roll on?

Durability is another critical factor. Choose materials that resist wear and tear. Common materials include rubber and polyurethane. These options tend to last longer, especially in high-traffic areas. Don't overlook the swivel radius. A larger radius means better maneuverability. However, it may not fit in tighter spaces.

Tip: Test the swivel motion before purchase. Is it smooth?

Understanding these aspects can guide your selection effectively. Make informed choices to enhance operational efficiency.

Essential Tips for Choosing the Right Swivel Plate Caster

| Dimension | Description | Example Applications |

|---|---|---|

| Load Capacity | The maximum weight a caster can support. | Industrial trolleys, furniture, equipment carts. |

| Wheel Diameter | The diameter of the wheel affects mobility and load distribution. | Hand carts, pallet jacks. |

| Material | The material of the wheel impacts durability and suitability for surfaces. | Warehouse logistics, medical equipment. |

| Swivel Radius | The space required for the caster to pivot. | Shopping carts, hospital beds. |

| Brake Type | Different brake types provide varying levels of safety and control. | Workshop equipment, moving stands. |

Factors to Consider When Selecting Swivel Plate Casters

When selecting swivel plate casters, consider the weight capacity. Each caster has a limit. Using a caster that cannot support the load can lead to failure. Check the weight of your items plus any extra you may add. It's better to choose a caster with a higher capacity than needed.

The wheel material affects performance. Hard wheels are great for smooth surfaces but can scratch floors. Softer wheels are quieter and safer on delicate surfaces. Think about your environment. Choose wisely to avoid damaging equipment or flooring. The wheel diameter also matters; larger wheels roll more easily over obstacles.

Look at the swivel range. Casters with a wider swivel angle offer better maneuverability. However, too much swivel can lead to instability. Evaluate your space. Test which swivel degree works best for your needs. Always double-check your choices. An overlooked detail can cost time and money.

Material Types and Their Impact on Performance

When selecting a swivel plate caster, the material type plays a key role in its performance. Common options include plastic, rubber, and metal, each providing unique benefits. For instance, rubber casters are ideal for delicate floors. They offer a quiet operation and absorb shock well. However, they may wear out faster in rugged environments.

Plastic casters are lightweight and resistant to corrosion. They work well in warehouse settings. But, they might not provide the best stability. It's crucial to choose a material that aligns with your specific needs. Metal casters, like steel, offer strength and durability. They can handle heavy loads but can scratch floors easily.

Tips for choosing the right material include evaluating the floor surface. Smooth surfaces might benefit from softer materials. Heavier loads require stronger options. Assess the environment too; outdoor settings demand more durable choices. Remember to review weight capacities and wheel sizes. The right mix will enhance mobility and extend the caster's life.

Essential Tips for Choosing the Right Swivel Plate Caster

This chart illustrates the average load capacities of different types of swivel plate caster materials. Selecting the appropriate material significantly impacts the performance, durability, and application of the caster.

Weight Capacity and Load Distribution Guidelines

When selecting a swivel plate caster, understanding weight capacity is crucial. Each caster has a maximum load it can handle. Exceeding this limit can cause failure. To determine the right capacity, consider the total weight of the items you plan to move. This includes not only the object’s weight but also the load distribution across the caster.

Proper load distribution impacts the performance of the caster. Uneven weight can lead to premature wear or even accidents. Spreading weight evenly among multiple casters can enhance stability. For instance, a heavy table should have several casters beneath to avoid excessive pressure on any single point.

Reflect on your specific needs. The work environment influences the required load capacity. Indoor and outdoor conditions can vary. Surfaces may be smooth or rough, affecting the choice of caster. A miscalculation in capacity or load distribution could lead to frustration. Regularly assess whether your casters meet your demands, as usage patterns might change over time.

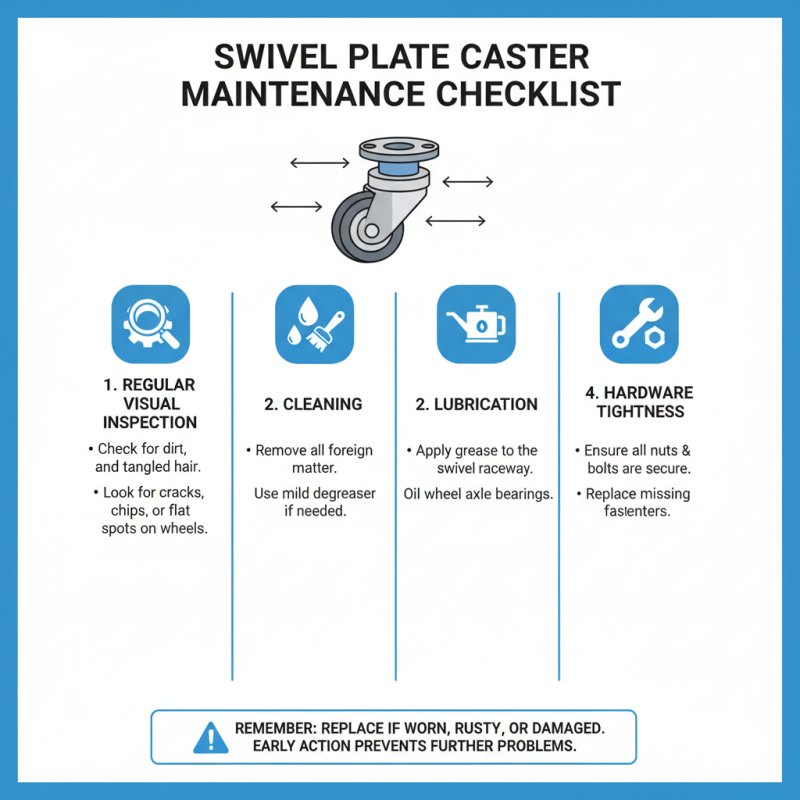

Maintenance Tips for Maximizing Caster Lifespan

When it comes to maintaining swivel plate casters, regular check-ups are key. Dirt and debris can clog wheels. This can impact their mobility and lifespan. A simple visual inspection can reveal a lot. Look for any signs of wear, rust, or damage. If you see any, it may be time for a replacement. Remember, waiting too long can worsen the problem.

Lubrication is another vital aspect. Caster wheels can dry out and become stiff over time. Use appropriate lubricant to keep them rolling smoothly. A little goes a long way. However, too much lubricant can attract dirt, creating more issues. It’s a balance that takes some practice.

Finally, consider the surface where your casters operate. Rough terrain can lead to faster wear and tear. If your casters frequently encounter such surfaces, rethink your choice of wheels. It’s essential to adapt your casters to meet your specific needs. The right decisions will save you time and money in the long run.

Related Posts

-

Navigating Export Certification for Best Heavy Caster Wheels: A Guide for Global Buyers

-

Understanding the Challenges of Heavy Caster Wheels in Industrial Applications

-

Understanding the Differences Between Swivel Plate Casters and Fixed Casters

-

What Are the Key Features of Caster Trolley Wheels

-

7 Essential Tips for Choosing the Right Vintage Metal Caster Wheels

-

How to Choose the Right Caster Trolley Wheels for Your Needs